In many industries, safety is a top priority. Whether you work in construction, road maintenance, or any other profession where visibility and protection are crucial, safety work vests are an essential piece of equipment. These vests are specifically designed to provide maximum visibility and protection for workers, helping to prevent accidents and ensure a safer work environment. In this comprehensive guide, we will explore the benefits of safety work vests and provide an overview of the different types available in the market today.

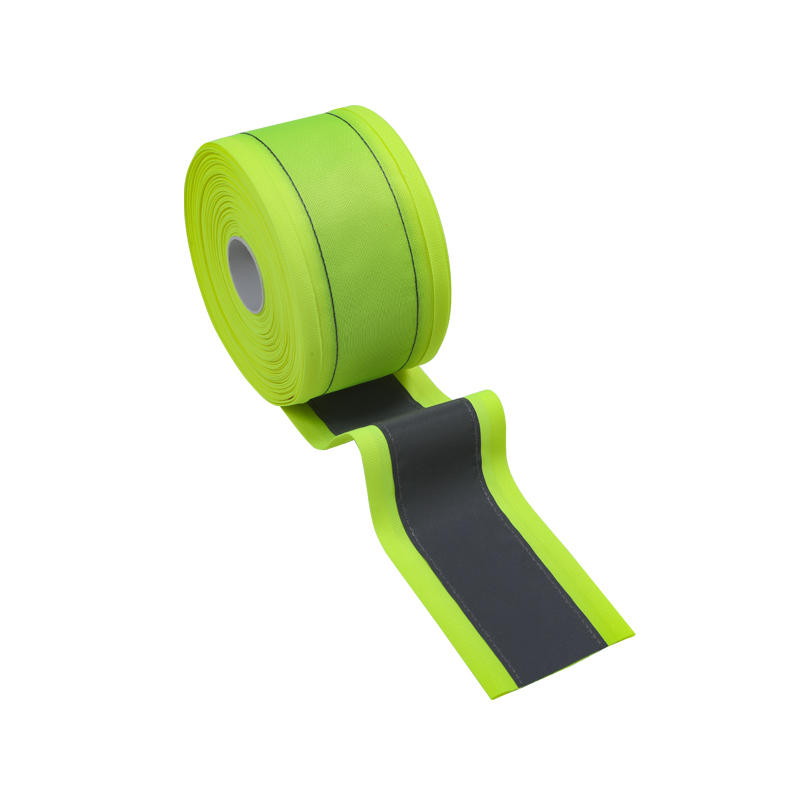

Visibility: One of the primary purposes of safety work vests is to enhance visibility. Bright colors and reflective tapes are often used to make workers stand out, especially in low-light conditions or high-traffic areas. The fluorescent colors, such as lime green or orange, are highly visible during the day, while the reflective tapes reflect light at night or in dimly lit areas. This increased visibility makes it easier for others, such as drivers or heavy machinery operators, to spot workers and take appropriate precautions.

Protection: Safety work vests provide more than just visibility. They also offer protection against various workplace hazards. Some vests are designed with additional features like high-visibility patterns, flame-retardant materials, or tear-resistant fabrics. Depending on the nature of your work, you can choose vests with specific protective properties to enhance safety and minimize the risk of injuries.

Types of Safety Work Vests:

1. Class 1 Vests: These vests are suitable for low-traffic areas where the speed limit is below 25mph. They typically have less reflective material but still provide basic visibility and protection.

2. Class 2 Vests: Class 2 vests are appropriate for work environments with higher traffic speeds, typically ranging from 25mph to 50mph. They feature more reflective material and additional design elements to enhance visibility.

3. Class 3 Vests: Class 3 vests are the most visible and provide the highest level of protection. They are designed for workers in high-speed traffic areas, where visibility is crucial for ensuring workers' safety.

4. Breakaway Vests: These vests are equipped with breakaway closures that release easily when pulled from any direction. They are specifically designed for situations where workers might get caught on machinery or equipment, allowing for a quick escape and minimizing the risk of injury.

5. Flame-Resistant Vests: For workers in environments where flames or sparks are present, flame-resistant vests offer an additional layer of protection. These vests are made from fire-resistant materials, reducing the risk of burns and injuries.

Fit and Comfort: In addition to safety features, it's important to consider the fit and comfort of the safety work vests. Vests should be adjustable to accommodate different body sizes and shapes. They should allow for freedom of movement, ensuring that workers can perform their tasks without restriction. Additionally, lightweight and breathable materials can help prevent overheating and discomfort during long hours of work.

Maintenance and Care: To ensure the longevity and effectiveness of safety work vests, proper maintenance is essential. It's important to follow manufacturer guidelines regarding washing and drying instructions. Regular inspection should also be conducted to check for any signs of wear or damage, as compromised vests will not provide the same level of protection.

In conclusion, safety work vests are an indispensable component of personal protective equipment in various industries. Whether for visibility or protection, Safety work vest factory play a crucial role in keeping workers safe on the job. By understanding the different types of vests available and considering factors such as fit, comfort, and maintenance, you can make informed decisions when choosing the right safety work vest for your specific workplace needs.